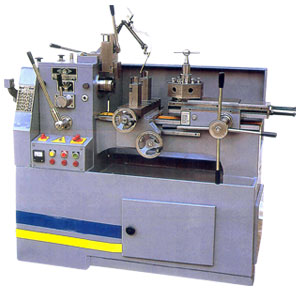

Capstan Lathe

HPSM’ Capstan Lathes are productive machines, suitable for Turning, Drilling, Boring, and Facing & Threading with full Norton Gear Box with Semi-Skilled operating pieces of Jaw Chuck. Being a leading manufacturer of Capstan Lathes, we have dedicated workforce of highly trained professionals in their fields.

Having Hand & Auto longitudinally as well as Transverse feed. Threading range 4 to 60 T.P.I. through full Norten Gear Box, 4 speed is provided self shaft for fine & rough turning for Cross Slide & Turret feed. Also longitudinal stop provided.

STANDARD ACCESSORIES

Introduction

Capstan Lathes are productive machines, suitable for Turning, Drilling, Boring, Facing & Threading with full norton Gear Box with Semi-Skilled operating pieces of Jaw Chuck.

Cross Slide

Having Hand & Auto longitudinally as well as Transverse feed. Threading range 4 to 60 T.P.I. through full Norten Gear Box, 4 speed is provided self shaft for fine & rough turning for Cross Slide & Turret feed. Also longitudinal stop provided.

Head Stock

All geared & running parts of Head Stock are Heat-Treated & Ground Mounted on Heavy Duty Tapered Roller Bearings & runing in oil bath.

Turret Head

The Turret Slide is provided with longitudinal power feed & hand operated feed. Longitudinal stop is also provided & the Stop Rod revolves automatically together with the rotating Turret Head.

Salient Features

- Hardened & Ground standarised spindle with standard fitting of A-20. Compact design for small components.

- Hardened & ground standarised spindle with standard fittings of A-25. Precision Run out. back Operated Center.

- Taper nose handened & Ground alloy steel spindle with precision run out. Well ribbed & ground ways of bed. Multi disc friction clutch of 8 kgf. is provided in head stock for quick variation in speed.

- Spindle with Standardised fittings & A-40 collet with 6 speed head stock fitted with friction clutch. Well ribbed & Ground ways of Bed.

- Standarised Spindle with Standard fittings of A-25. Well Ribbed & Ground ways of Bed.

- Hand operated dead length bar Chuck, One collet, Cross Slide with two tool posts. Bar feed, Spalash guard, Spanner set, Allenkey set.

Standard Equipement

- Hand operated dead length bar Chuck, One collet, Cross Slide with two tool posts. Bar feed, Spalash guard, Spanner set, Allenkey set.

- One couplin 165mm for Spindle taper nose, Cross slide with two tool posts, Manual turret, Spanner set, Allenkey set, oil cane and Motor pulley.

Extra Equipment

- Vertical Slide

- Chuck Plate

- Coolant Pump & its fittings & Panel Board

- 2 h.p. isi marked Motor

- Screw Operated tail stock

- Coolant Pump

- Panel Board

- Bar Feed Attachment

- Collet Chuck

- 3 h.p. isi marked Motor

- Feed for turret slide

| Technical Specifications | ||||||||

| HPS-60G | HPS-50G | HPS-40G | HPS-32G | HPS-25G | HPS-25S | HPS-20S | ||

| Spindle Hollow | 62 | 52 | 42 | 38 | 32 | 28 | 25 | |

| Maximum Collet Capacity | 60 | 50 | 40 | 32 | 25 | 25 | 20 | |

| Range of Spindle Speeds | 90-1000 | 100-1050 | 165-1500 | 165-1500 | 275-900 | 650-1660 | 650 x 1660 | |

| Effective Strokes of Turret Slide | 180 | 175 | 140 | 140 | 130 | 110 | 100 | |

| Bore Size in Turret Hex Head | 32 | 32 | 32 | 25 | 25 | 25 | 25 | |

| Center of Holes above Turret Slide | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| Max. distance between spindle nose to turret face | 430 | 430 | 425 | 425 | 400 | 375 | 300 | |

| Cross slide Transverse Travel | 150 | 150 | 95 | 95 | 95 | 95 | 95 | |

| Cross Slide Longitudinal | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Length of Bed | 1375 | 1375 | 1225 | 1225 | 1275 | 1050 | 980 | |

| Width of Bed | 230 | 230 | 178 | 175 | 178 | 178 | 178 | |

| Height of Center above Bed | 190 | 190 | 165 | 165 | 165 | 165 | 165 | |

| Floor Space required | 3m x 1m | 3m x 1m | 3m x 1m | 3m x 1m | 3m x 1m | 2.5m x 1m | 2.5m x 1m | |

| Net Weight of Machine | 1850 | 1850 | 1250 | 1150 | 850 | 650 | 500 | |

| Packing Size (Approx) | 5 x 3 x 5 fts. | 5 x 3 x 5 fts. | 5 x 3 x 5 fts. | 5 x 3 x 5 fts. | 4.5 x 3 x 5 fts. | 4 x 3 x 5 fts | 4 x 3 x 5 fts. | |